CNC precision machining addresses complexity and dimension precision. The automation and small human intervention from the operation of CNC tools permit for stringent tolerances.

You will need precision grinders in the event you have to have CNC precision machining that gives easy surface area roughness requirements.

CNC turning may perhaps experience troubles when dealing with products which might be tough to cut or vulnerable to chipping, limiting its applicability in selected manufacturing scenarios.

By combining milling and turning abilities, these machines greatly enhance effectiveness, decrease set up situations, and grow the scope of achievable geometries in machining procedures.

Furthermore, appropriate elements for precision CNC elements should be picked according to the required performance with the pieces and also the operational atmosphere.

In addition, the precision CNC turning approach crafts intricate information and styles as a result of workpiece rotation in lieu of cutting equipment. The stationery Resource can transfer throughout the workpiece for your precise content elimination procedure.

In this article, we’ve gathered some simple facts and essential things to consider that may help you obtain the specified final results.

To be able to preserve the two the bit and content amazing, a superior temperature coolant is used. In most cases the coolant is sprayed from the hose specifically on to the bit and content. This coolant can possibly be machine or person controlled, with regards to the machine.

Electrical market: You’ll uncover s CNC machines generating holes in printed circuit boards and earning copper heat sinks.

A saddle that’s underneath the worktable, for added guidance and to help keep the worktable’s movement parallel towards the Resource’s rotating axis

Altering the CNC machining variables and tooling setup enables us to accommodate various supplies, from tough titanium grades to comfortable aluminum and plastics.

The Finnish orthography using the Latin script was according to People of Swedish, German and Latin, and was initially used from the mid-sixteenth century. No previously script is known. Begin to see the Wikipedia posting on Finnish To learn more, and S for information on the development of your glyph by itself.

The very higher level of precision needed in the aerospace market will make CNC machining an appropriate manufacturing course of action to the sector.

The deal with-milled characteristics contain flat surfaces and shallow cavities, though the peripheral milled capabilities are deeper cavities like threads and slots. Precision CNC milling machines enable develop mostly sq.- and rectangular-formed parts with a variety of functions.

Kel Mitchell Then & Now!

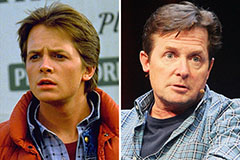

Kel Mitchell Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Suri Cruise Then & Now!

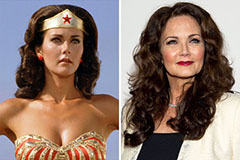

Suri Cruise Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!